I was once asked: “Hey Nate!! I hooked a solar panel to the batteries of my camper, and I still can’t power my popcorn maker. What’s wrong?”

And that’s a good question, but simply attaching a solar panel to an RV and wondering why it doesn’t power all your devices is like buying a Toyota Prius, adding a spoiler, and expecting it to win street races.

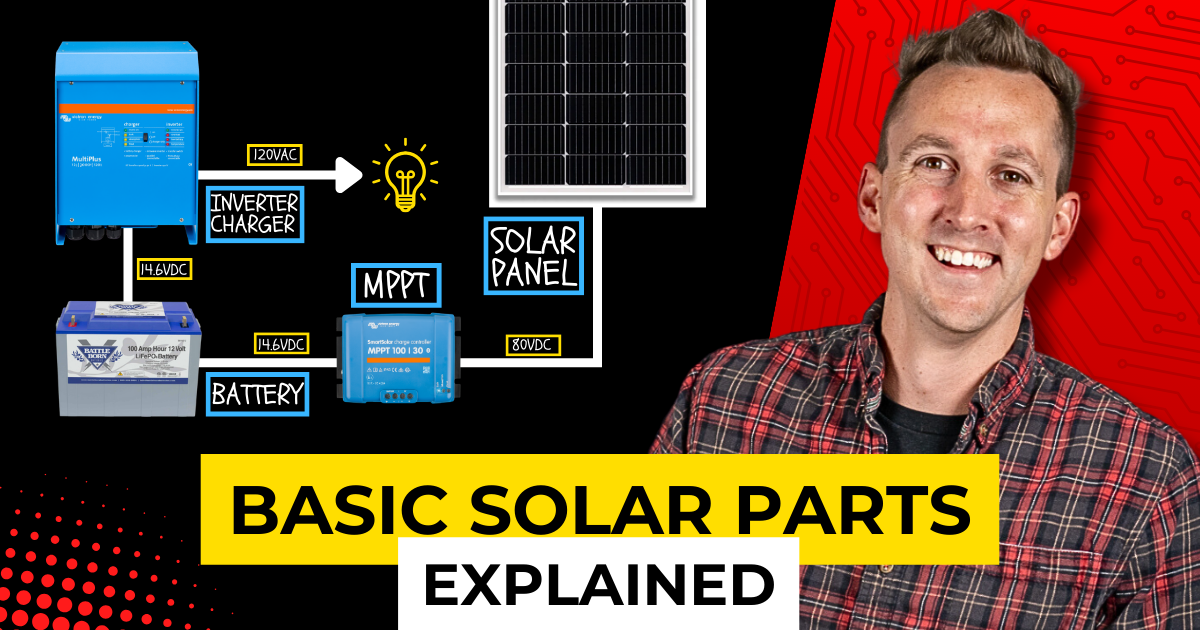

Cleaning up the confusion between all of the main parts and components of an electrical system like batteries, inverters, solar charge controllers and more is exactly what we are going to cover here in Lesson #2 of this Electrical Terminology Chapter of the EXPLORIST.life Electrical Academy

{{Coming Soon}}

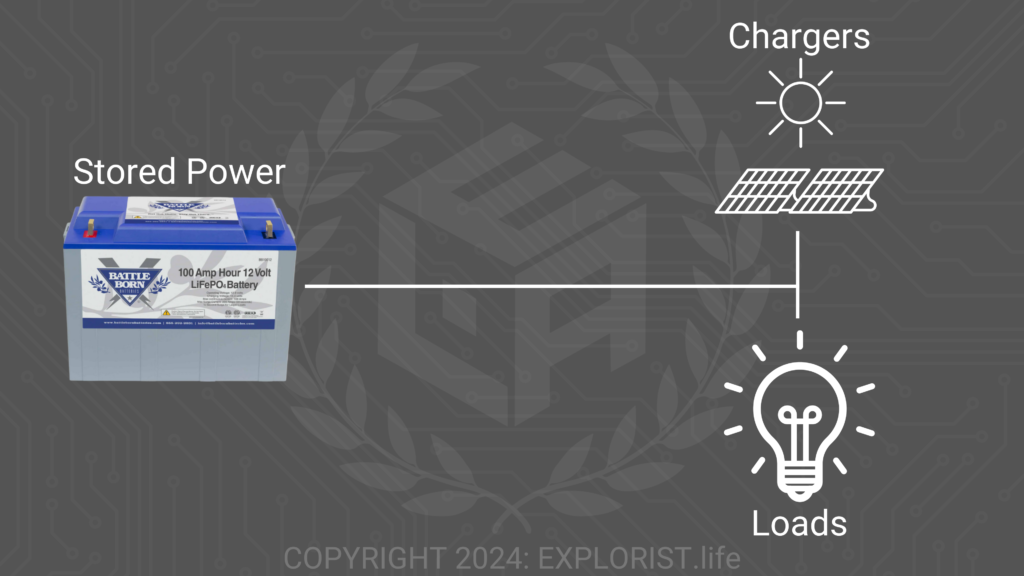

A battery is the backbone of any off-grid electrical system and serves as a power storage unit. While there are more advanced aspects to understand about batteries, such as the differences between 12V, 24V, and 48V battery banks or the advantages of lithium batteries over traditional lead-acid batteries, the key point is that batteries store power.

However, having a battery without a way to use the power and recharge it doesn’t do you any good. So, moving forward, we will discuss the three main methods to recharge a battery and the two ways to use the stored power, focusing on the necessary components for these processes along the way.

The first way to charge a battery is through solar power

A solar panel captures a fraction of the sun’s energy output – approximately 383 septillion (382,800,000,000,000,000,000,000,000) watts – and converts it into usable power for recharging off-grid electrical systems.

This process involves photons from the sun hitting the solar cells in a panel, initiating a photoelectric effect that generates voltage and wattage. BUT…

This 101-level video won’t go any further into the science of that but will focus on the fundamental concept that solar panels convert solar energy into usable power.

Solar panels vary in size, shape, and power output, ranging from the tiny panels used in calculators to large 500+ watt panels on the roof of a house. Generally, larger solar panels yield more power.

Despite the variety of solar panel chemistries and brands, no single type is significantly better. A demonstration done by Victron Energy comparing different solar panel types found only a 5% performance difference between the best and worst performers of that particular installation.

The takeaway is that solar panels are crucial for harvesting solar energy and converting it into a usable form.

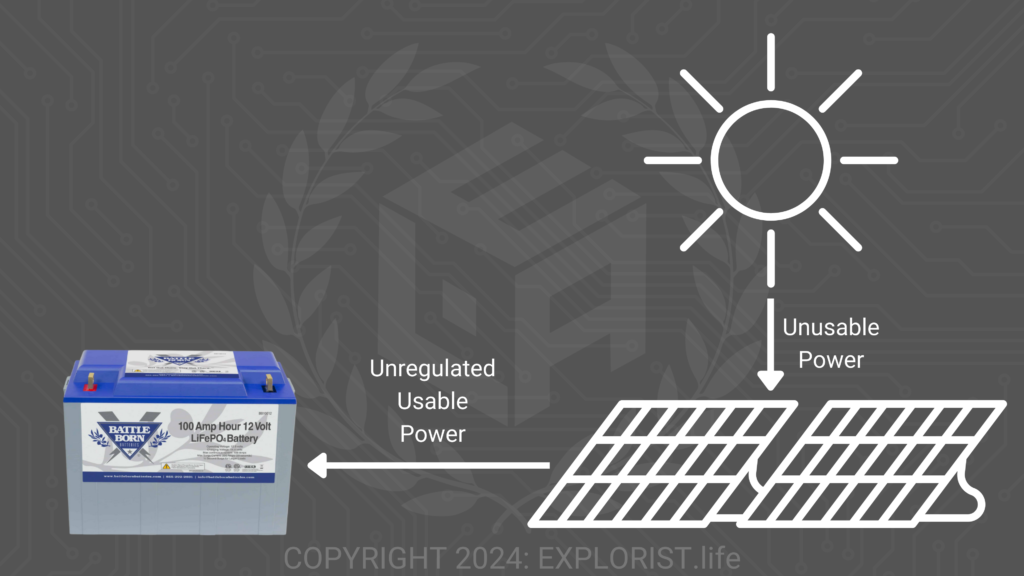

So, why can’t you simply connect a solar panel directly to your battery? Well, that’s because it will damage the battery. This leads us to the role of solar charge controllers.

Solar panels, especially when wired together, often operate at a voltage much higher than what a battery can safely handle. For instance, a series of solar panels might produce over 100 volts, which would be detrimental to a 12V battery designed for a maximum charging voltage of around 14.6V. This mismatch would likely destroy the battery, with the potential for rapid combustion.

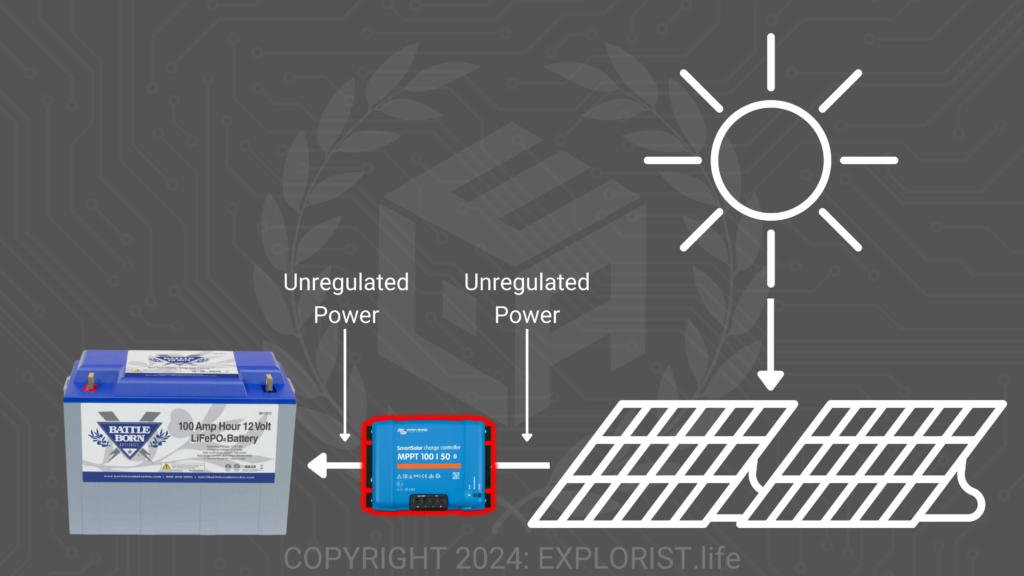

A solar charge controller addresses this issue by regulating the power from the solar panels and converting it to a suitable charging voltage for the battery. Charge controllers come in various sizes and specifications but perform the same function, differing primarily in voltage and amperage outputs.

The two main types of charge controllers are MPPT and PWM. PWM controllers, less sophisticated, are suitable for small arrays. MPPT controllers, which are newer and smarter, offer more flexibility in wiring and have become much more affordable, making them our preferred choice for all of the systems we sell in our store.

As a recap: solar panels capture and forward energy to the solar charge controller, which then regulates this energy into a voltage more appropriate for battery recharging.

The next way to charge a battery is through the vehicle alternator

When the engine in your vehicle (be it a van, motorhome, skoolie, or RV tow vehicle) is running, it spins the alternator, which produces electricity. This electricity powers things like the radio, fuel pump, and headlights. Typically, alternators are designed with some extra capacity for additional devices like stereo systems, winches, extra lights, or, in our context, a DC-DC Charger.

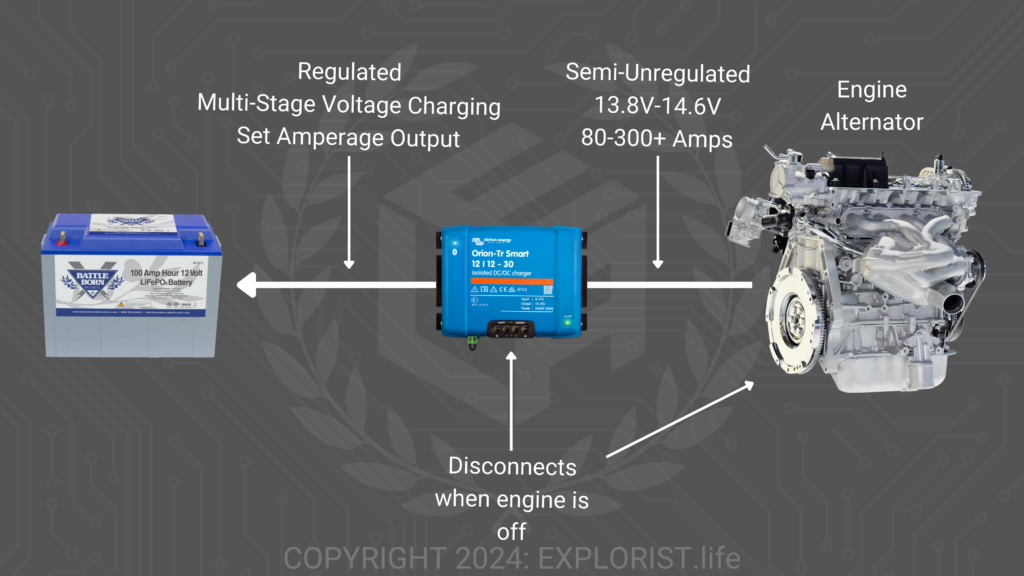

A DC-DC charger functions similarly to a solar charge controller, transforming the power generated by the alternator into a form suitable for charging a battery bank. Often, the voltage from an alternator is too low for effectively recharging a house battery bank. The DC-DC charger boosts this voltage to ensure complete battery charging.

Additionally, it regulates the amperage from the alternator to prevent overheating and potential damage to the alternator due to over-use.

As a recap: The engine spins the alternator, producing electrical power, which the DC-DC charger then regulates the voltage and amperage to recharge the house battery bank.

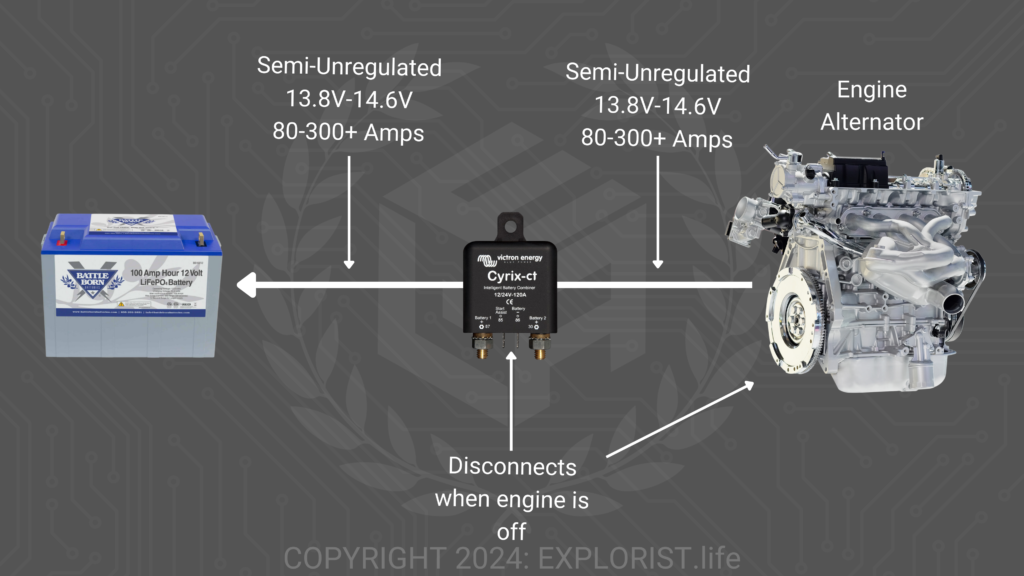

A battery isolator is a simpler, less sophisticated device for alternator charging than a DC DC Charger. It is a switch that connects or disconnects the alternator from the house battery bank based on voltage levels

When the engine runs, the voltage from the alternator rises, causing the isolator to connect, allowing the house battery bank to charge.

When the engine stops, the alternator voltage drops, causing the isolator to disconnect, and preventing the starter battery from draining while parked.

Isolators, being less sophisticated, don’t regulate the amperage from the alternator. This can be problematic with lithium battery banks, which might draw excessive power, potentially overheating the alternator. Some advanced isolators, like the Battleborn’s LIBIM, cycle on and off to allow the alternator to cool, although this can limit the charging capacity while driving.

Given these complexities and potential risks, we at EXPLORIST.life typically recommend DC-DC chargers for alternator charging, (rather than battery isolators) favoring their programmability and consistency.

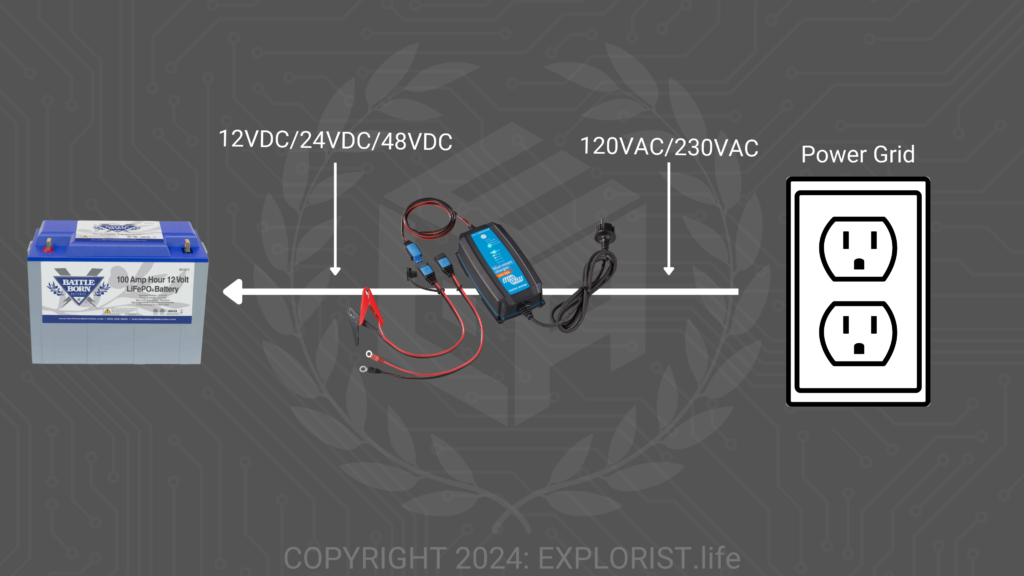

Shore power is another method to charge off-grid electrical systems, commonly used in vans, motorhomes, RVs, and boats. It involves connecting to grid power from sources like campground power pedestals or residential outlets.

While connected to the grid, the system isn’t technically off-grid, but shore power remains a crucial recharge method for mobile applications. AC Power flows from the shore power source into the system’s battery charger, which then converts it into a DC voltage suitable for charging the battery bank.

For example, when charging a 12V battery bank from a standard U.S. household outlet, the charger converts the 120V AC current into the 14.6V DC current required for the battery.

If you have a different battery bank voltage or live in a different country with a different grid voltage, there are shore power chargers available for all of those combinations as well.

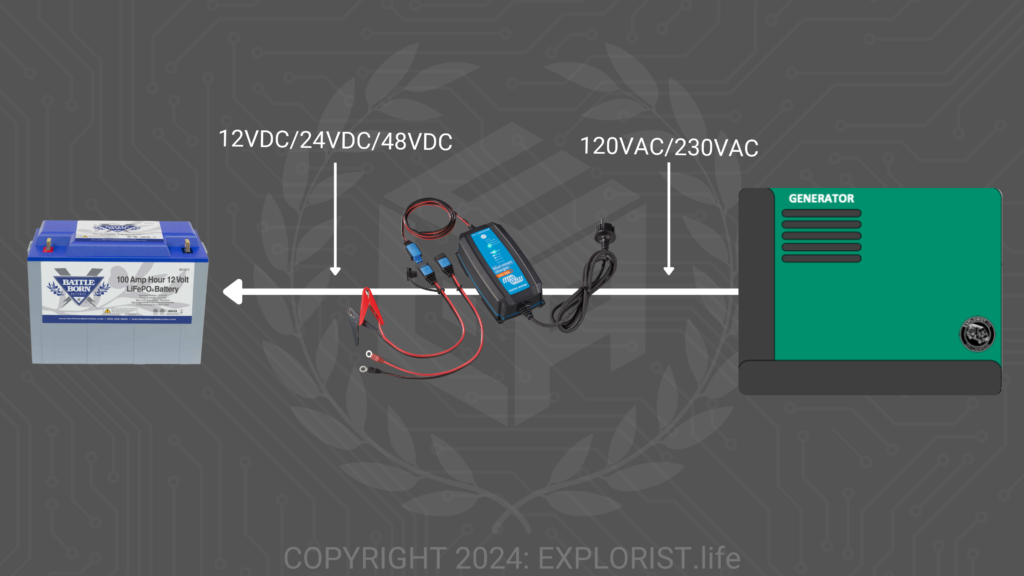

While discussing shore power, it makes sense to also talk about generators. A generator is an internal combustion engine designed to create electricity. It burns fuel, such as gasoline, diesel, or propane, to spin an alternator that generates electrical output. In our off-grid electrical systems, generators and shore power can be thought of as electrically the same.

For example, here in the USA, Electrical power from a generator is typically 120V AC, which is then fed into the system’s battery charger. This charger converts the 120V AC from the generator into the appropriate DC voltage needed to charge a 12V battery; exactly like what happens with shore power.

The three primary methods for charging house battery banks in vans, RVs, motorhomes, and boats are solar, alternator, and shore power, often with a generator backup. However, there are additional charging systems suitable for different applications. For instance, off-grid cabins might utilize wind energy via windmills or hydropower from running water sources.

While we won’t get into these methods in this video, it’s important to understand that both wind and hydropower involve spinning something to generate power, which then needs to be converted to a suitable voltage and amperage for charging a house battery bank. This concept mirrors the principles we’ve already discussed with other charging methods.

So, moving forward…How Do We Use This Stored Power?

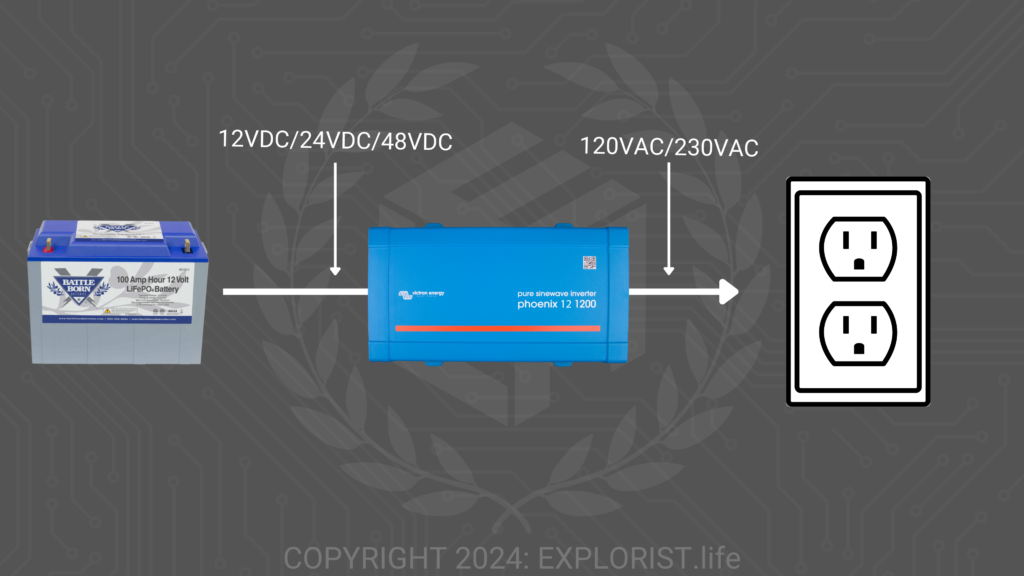

An inverter plays a critical role in any off-grid system. It Converts the DC power stored in a battery to AC power, which is necessary to run standard household appliances. For instance, in countries with 120V AC grids, an inverter will transform 12V DC, 24V DC, or 48V DC stored in a battery to 120V AC. Similarly, in regions with 230V AC grid power, inverters are available to match those requirements as well.

Depending on the situation we can even provide 3-phase power or split-phase power from an Inverter, which we won’t get into in this 101-level tutorial. There are all kinds of options, but the main thing to know is that The essential function of an inverter is to provide AC power for standard household devices from DC power stored in a battery bank.

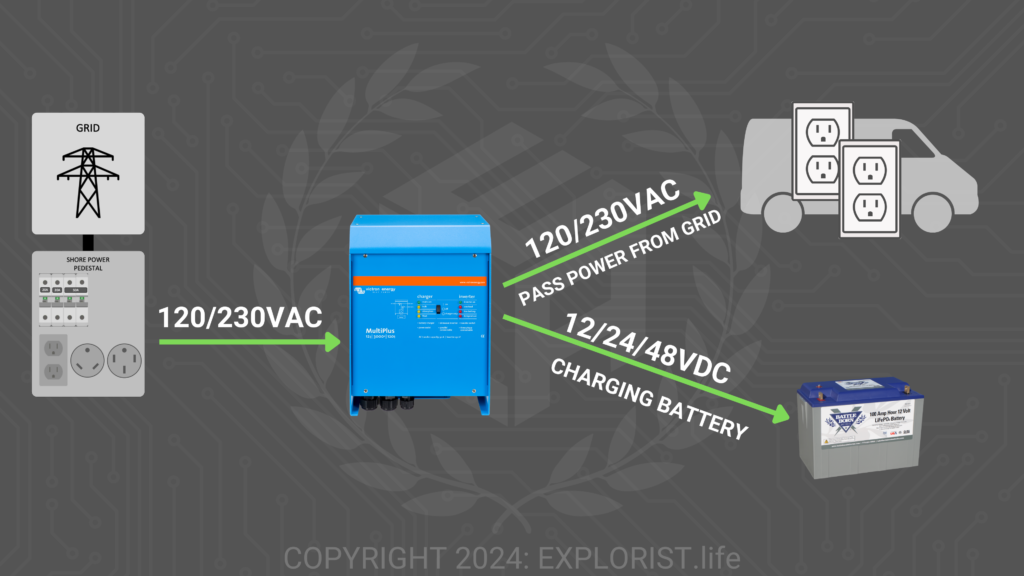

An inverter charger is a device that combines the capabilities of a shore power battery charger and an inverter all-in-one. When connected to shore power, it passes AC power directly through to the system’s outlets. Any surplus AC power is then converted to DC power, by the charger function, to recharge the house battery.

When disconnected from shore power, the inverter portion of the device takes over, powering all AC outlets from the DC power stored in the battery bank. We use inverter chargers in nearly all systems designed at EXPLORIST.life due to their streamlined functionality, combining an inverter and shore power charger, and eliminating the need for external transfer switches and extra wiring.

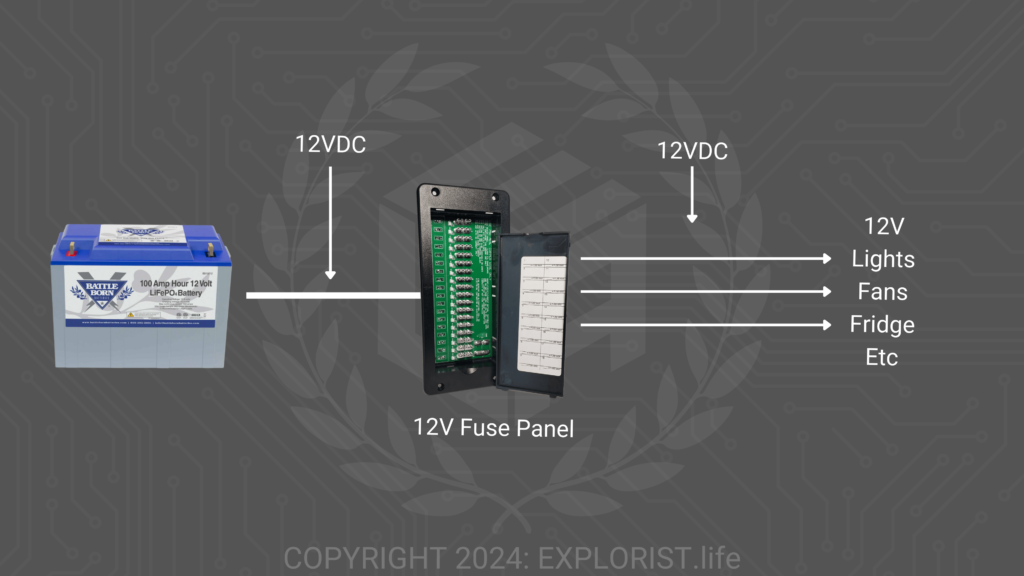

In vehicles like vans, motorhomes, RVs, or boats, there are numerous 12V loads such as lights, fans, and refrigerators. If you have a 12V battery bank, no additional devices are needed to convert power for these loads.

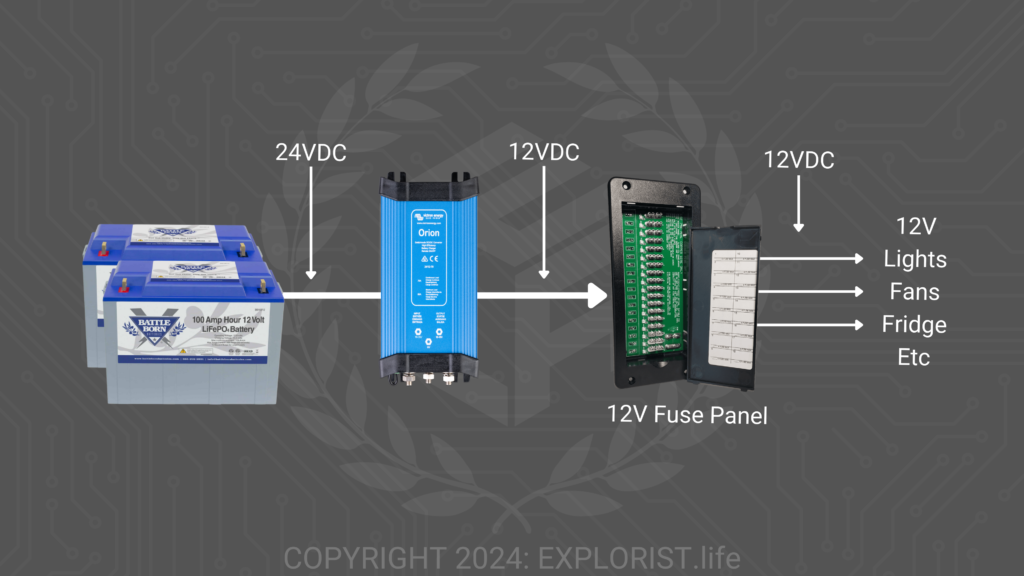

Most 12V appliances operate within a voltage range, so powering them directly from a 12V battery bank is typically not a problem. However, if your system includes 12V loads but uses 24V or 48V battery bank, a DC-to-DC converter is necessary. We’ll discuss why you might choose a 24V or 48V battery bank over a 12V battery bank in a future video, so consider subscribing.

A DC-to-DC converter adjusts one DC voltage level to another. For example, in a system with 12V loads and a 24V battery bank, a DC-to-DC converter would be used to step down the 24V from the batteries to the 12V needed for the appliances.

Now that we’ve covered power conversion let’s discuss power transmission, safety, and protection mechanisms, like wires, fuses & breakers.

Wires are strands of copper used to transmit electricity from one part of an electrical system to another. They vary in size, flexibility, and type, with some being stranded and others solid.

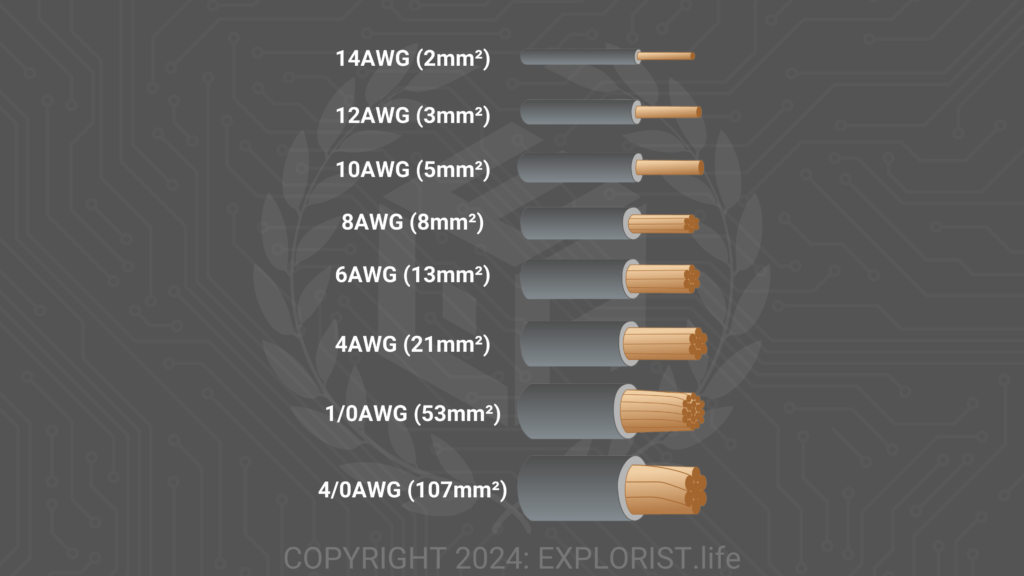

The important thing here is that the size of a wire is crucial for its intended purpose. In the U.S., wire sizes are categorized by gauge, with common sizes ranging from 18ga wire being the smallest we use to 4/0 for much larger devices. In most other countries, wire sizes are typically referred to by their millimeter-squared area equivalent.

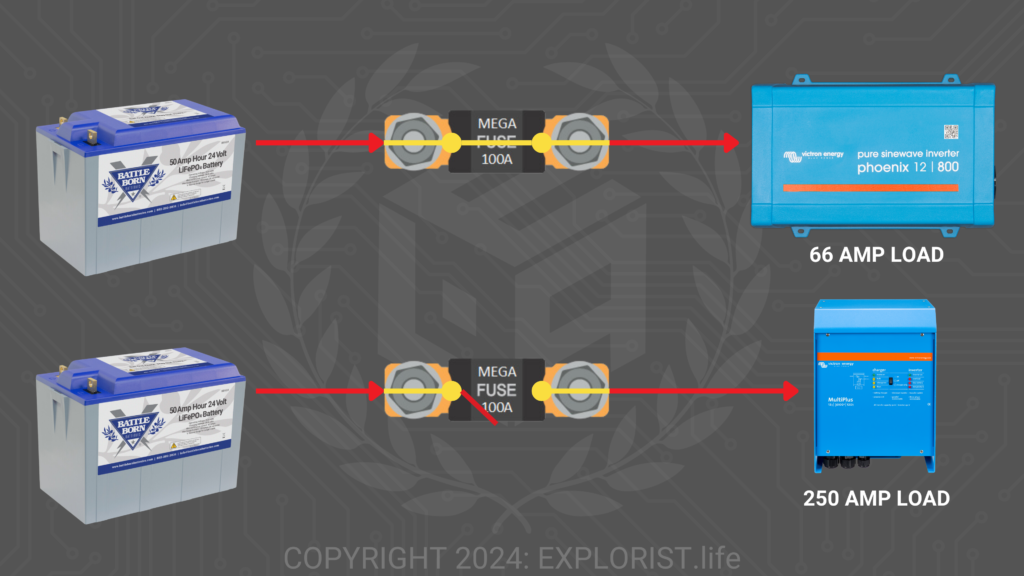

A fuse is an overcurrent protection device that protects wires during excessive current flow. Overcurrent events can occur in various scenarios, such as a direct short which is when a positive and negative wire touch each other, causing a lot of power to flow. Without a fuse, this could lead to a fire. However, with a fuse, its internal filament will melt, stopping the flow of power and preventing damage.

A poorly designed system can also cause overcurrent issues, where a load demands more power than a wire can safely handle, causing a wire to overheat. A well-designed system will have fuses that melt before the wires can reach a dangerous temperature, stopping the flow of power and avoiding rapid combustion.

There are many types of fuses, each with different specifications, but their fundamental purpose remains the same: to protect the electrical system from overcurrent events.

Circuit breakers serve a similar function to fuses. They provide overcurrent protection but can be manually switched on and off. This functionality makes breakers reusable and convenient for manually managing power flow and automatically protecting the system against overcurrent events.

A simple example of a breaker is going to be your household breaker box. All of these breakers protect the wires and outlets throughout your entire house.

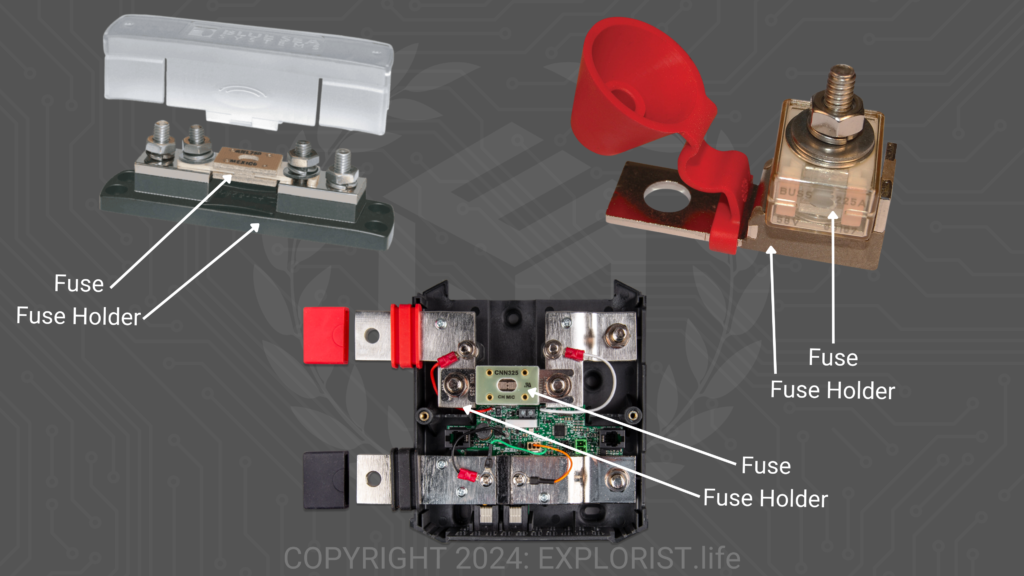

A fuse holder is a component that holds a fuse.

A fuse alone is not designed to function without a holder, the holder provides a secure and stable platform for the fuse’s operation. A single fuse holder might be a simple device with connections for wires on each side, or it can be part of a more comprehensive distribution panel, housing multiple fuse holders and a bus bar.

An example of a distribution panel is the Victron Lynx Distributor. It’s designed for managing large DC loads like inverters, solar charge controllers, shore power battery chargers, and for powering secondary 12V fuse panels.

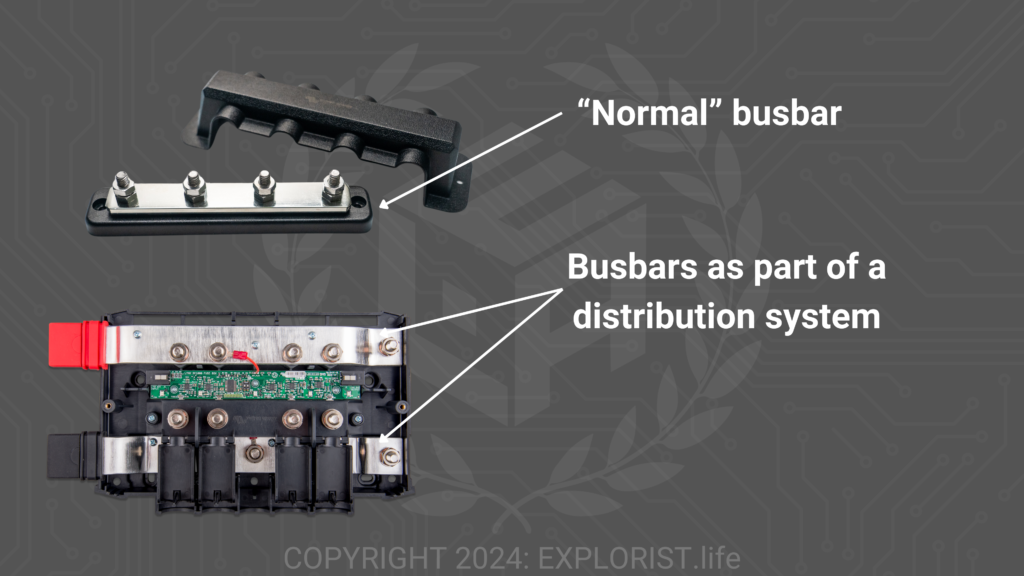

Bus bars are solid copper bars equipped with built-in studs for attaching wires and fuses. They come in various sizes and designs, some with integrated fuse holders.

Bus bars are essential for distributing high-amperage power throughout an electrical system, especially when paired with fuse holders like those in the Victron Lynx Distributor or the Blue Sea Safety Hub.

Wire terminals are the pieces crimped onto the ends of wires that let us connect the wires to various system components. For example, a large gauge wire connecting to an inverter might require a lug, while a smaller gauge wire for a fuse block may need a ring terminal. There are many types of terminals, such as spade, pin, PV connectors, and Deutsch connectors, each designed to connect wires to specific components. And no… just looping wire around a stud is generally not an acceptable practice unless that’s specifically how the terminal is designed.

Heat shrink is a tube of rubberized plastic that shrinks when heated. It’s used to cover the connection points of terminals on wires, providing extra protection and strain relief. The heat shrink used in our kits includes a heat-activated adhesive interior, sealing out moisture and adding further strain relief.

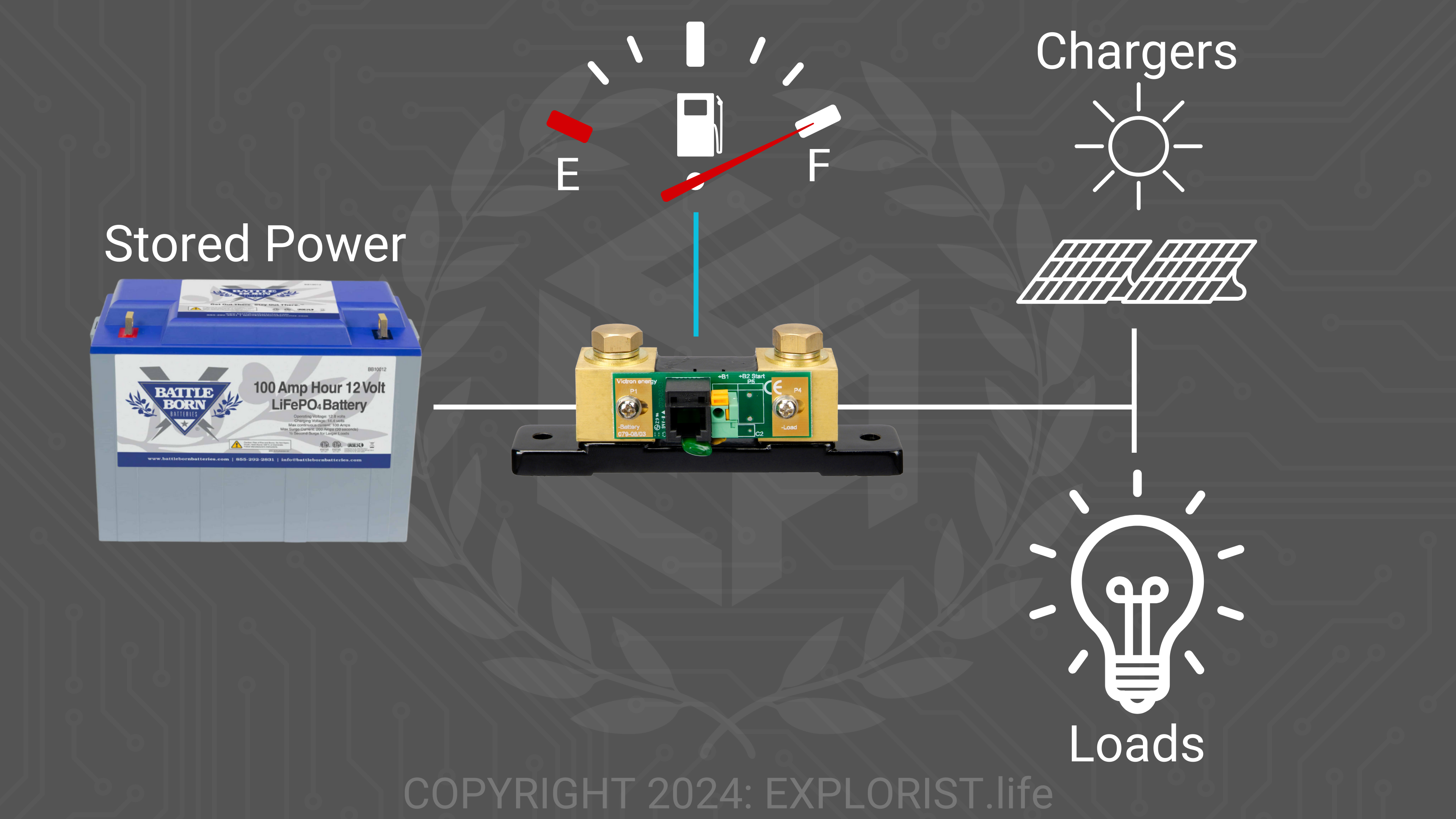

A shunt is an electrical measuring device installed on the negative wire from the battery bank to the rest of the system. It measures the power flowing in and out of the battery bank, providing vital data on the state of charge or discharge. While it’s not mandatory for an off-grid electrical system, not having a shunt is like driving without a fuel gauge – you can operate without it, but you’re missing Important information.

Now you should have a good idea of the basic parts and components found in an off-grid electrical system, and we are going to be referring to all of these parts in-depth as this academy moves forward; so be sure to bookmark this lesson for future reference and come back to it when you need a refresher.

When you are installing, designing, or troubleshooting an off-grid electrical system; knowing the parts and components is just one piece of the puzzle. Up next, I’m going to teach you the basic math behind how the components influence the electricity flowing through the system and how to convert from one unit to another.