Green Battery Minerals and Volt Carbon Technologies are working together to develop battery anodes made with high-grade graphite. Testing of graphite refined from Green Battery’s Berkwood property confirmed its suitability for lithium-ion batteries, and now Volt has begun battery anode development using Green Battery graphite.

Using the super-jumbo flake graphite concentrate derived from rock samples provided by Green Battery, Volt’s Scarborough facility successfully executed a dry separation process, yielding a record-high total carbon content of 98.4%. The graphite underwent a straightforward mechanical reduction process to achieve battery-grade anode sizes without the need for additional purification treatment. This process used no harmful chemicals, and did not go through sphericalizing and coating—two costly and energy-consuming processes. (These two steps could be added in the future, and might improve battery performance.)

A team led by Volt Board Member Dr. Aiping Yu extensively characterized the graphite using techniques such as X-ray diffraction (XRD), inductively coupled plasma mass spectrometry (ICP-MS), and scanning electron microscopes (SEM), confirming its suitability for further battery anode development.

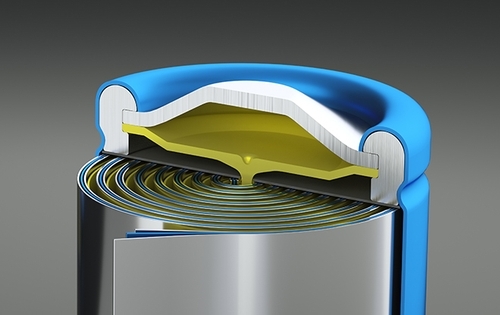

The researchers then manufactured coin cells alongside benchmarked samples of commercially available graphite anodes. Initial coin cell testing revealed a capacity of 344 mAh/g, achieved without any chemical processes, under entirely dry handling conditions, and without the use of spheroidization or carbon coating. With further process adjustments, the company aims to achieve results exceeding 360 mAh/g in the upcoming quarter.

“We have determined through testing that high-grade graphite mineral deposits provide significant advantages, making the processing to graphite concentrate and anodes much simpler compared to low-grade deposits,” said V-Bond Lee, CEO of Volt Carbon Technologies. “We’re on the brink of a great opportunity, and I’m eagerly looking forward to the upcoming results from our technical teams.”

“We are very impressed with Volt’s air separation process,” said Green Battery CEO Tom Yingling. “The process maintains the integrity of the large flake, which has good crystallinity and capacity for lithium-ion batteries.”

Source: Green Battery Minerals