Hexagon’s Manufacturing Intelligence division and JSOL Corporation have entered a strategic partnership to accelerate the virtual prototyping of electrified powertrains through multi-physics simulation. The collaboration builds on a long-term technical alliance offering global customers accurate and high-productivity virtual prototyping of complex electro-mechanical systems.

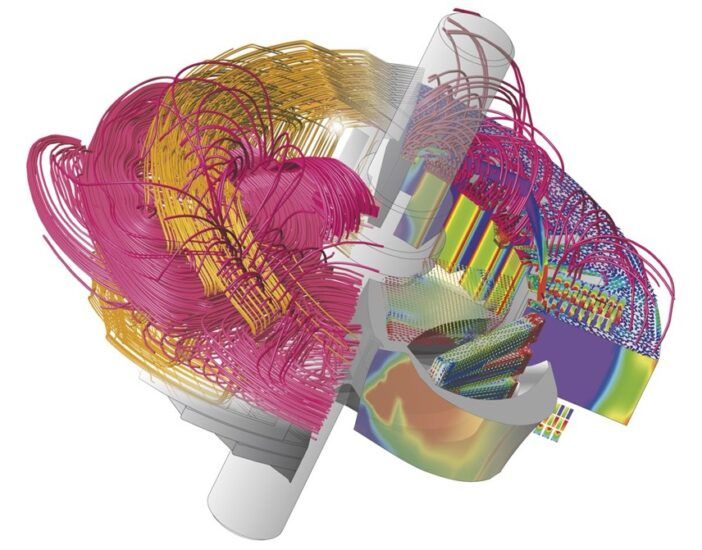

The rapid electrification of many industries, including automotive and aerospace transport, requires simulation technologies that enable cross-functional teams to understand the implications of component-level design choices on system-level integrity. Reliable prediction of their durability, efficiency, thermal management or noise and vibration requires a comprehensive simulation solution that can capture multi-physics effects at the component, subsystem, and system-level. The new strategic partnership will enable customers to combine Hexagon’s extensive engineering simulation software suite with JSOL Corporation’s JMAG electromagnetic field analysis software to solve a full spectrum of system design problems in the virtual world more quickly, thoroughly, and cost effectively than physical prototyping allows.

“As the move towards electrification accelerates, new challenges need to be addressed to improve vehicle performance characteristics, from the component to system level,” said Mahesh Kailasam, general manager of design and engineering at Hexagon’s Manufacturing Intelligence division. “For example, improvements to noise, vibration, and harshness (NVH) performance now require simulation solutions to provide answers at much higher frequency ranges. Our partnership with JSOL solidifies our commitment to serve our existing and new customers in this rapidly evolving market.”

To stay ahead in the market, electromagnetic powertrains need to be very efficient and light, using new designs, materials, and manufacturing techniques. Hexagon and JSOL offer digital platforms and virtual environments for engineers to develop advanced electric powertrain technologies.

“We are excited to work with Hexagon in this electrification journey,” said Takashi Yamada, chief technology officer at JMAG Business Company. “This partnership will now allow us to expedite electric vehicle NVH solution development between JMAG and Hexagon’s flagship products MSC Nastran and Adams, along with Romax and Actran.”

The partnership will advance several key areas to enhance their product design strategies for electric vehicles and enable more efficient and harmonious product development. A primary focus is to address NVH, enabling engineers to improve product comfort and reduce noise through innovative simulation-based design adjustments. Furthermore, by developing advanced simulations, the new solutions will inform robust and durable designs and make refinements to finalise products within space constraints. Another significant focus for the two companies is helping customers tackle the complexities of modern electro-mechanical machines, controls, and gearboxes with integrated solutions that foster collaboration between engineers from different disciplines.