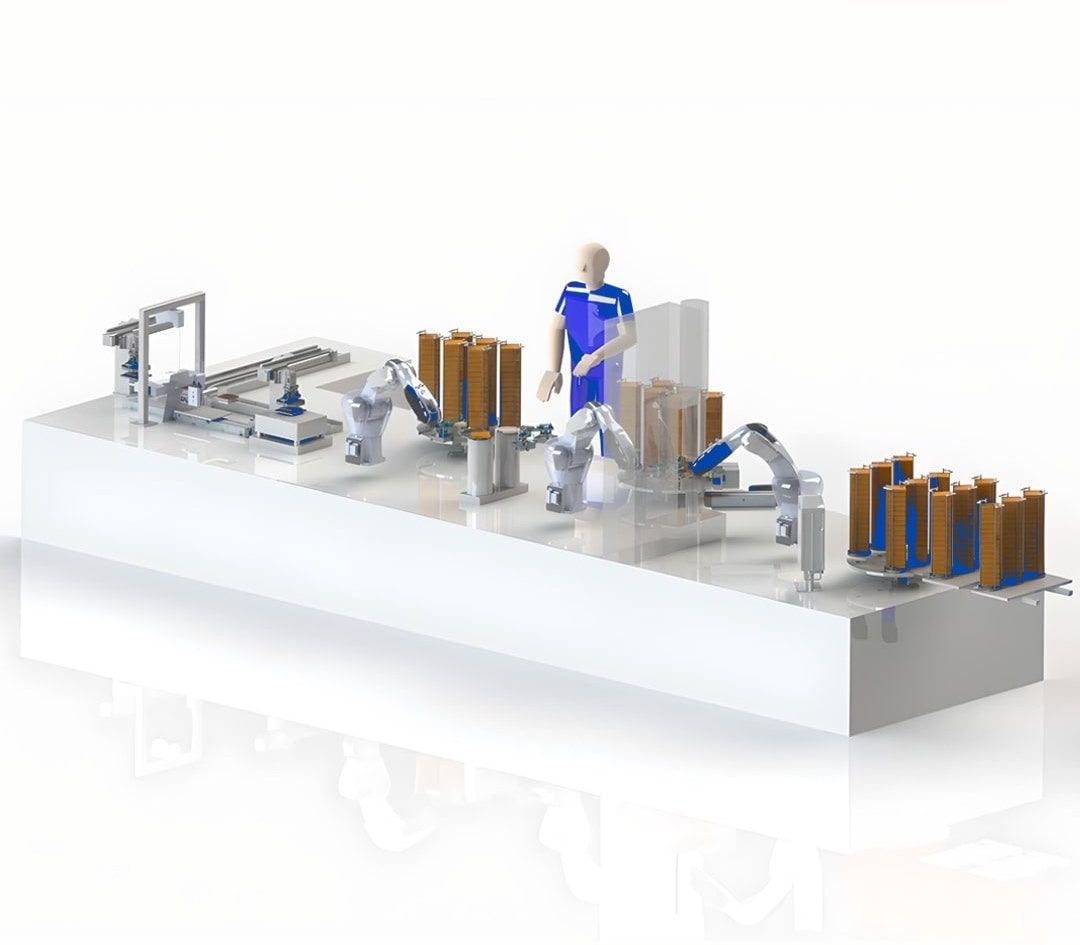

The companies have developed and validated an innovative and scalable manufacturing solution for solid-state sodium-metal-chloride battery cells. Through simultaneous engineering, the team has finalized a concept design, allowing LiNa, a leader in low cost solid-state sodium battery technologies, to automate their battery production process. The sustainable, safe, and efficient oxygen-free dry box environment is a step towards larger-scale manufacturing.

Working in tandem Comau and LiNa engineers designed the enclosure and handling equipment for the specific components of the solid-state battery cell as well as identified and integrated existing commercially available equipment. This collaborative approach enabled Comau to suggest modifications to LiNa’s existing manufacturing methodology with the aim of optimizing process dynamics in the move to automatic cell assembly.

Comau has provided LiNa with a detailed technology roadmap to automate their cell manufacturing process, leveraging its ongoing development of new manufacturing technologies for next-generation battery cells.

Development advances in sodium-based battery cells are driving the deployment of a safe, sustainable energy source that can be used at high temperatures. Instead of completely replacing lithium-ion batteries, next-generation solid-state sodium batteries will provide high performance energy storage that is both cost efficient and can be optimized for renewable energy integration in key solar growth markets such as India.

“This automated manufacturing concept, designed with Comau’s engineering team, provides a clear technology roadmap to significantly increase production capacity of our patented battery cells,” said Kris Barr, Director of Operations, LiNa. “Having successfully researched the process dynamics and finalized an innovative design proposal, we are looking forward to taking the next steps in our mission to commercialize our sustainable, low-cost solid-state sodium batteries.”

“Our steadfast commitment to energy transformation is a perfect match for a company like LiNa, whose vision and engineering competence are promoting and enabling the development of high-performance sodium-based energy storage solutions,” confirms Gian Carlo Tronzano, Head of e-Mobility Global Competence Center, Comau. “It was a great opportunity for us to have worked side-by-side to validate a manufacturing process design that will put LiNa on the path toward larger-scale industrialization of their solid-state sodium cell technology.”