One of the less obvious features of the Tesla Cybertruck is its vehicle voltage architecture. The Cybertruck is the first EV from the automaker to use a 48-Volt (48V) electrical system implementation throughout the entire vehicle, as compared to the 12V systems that are used in pretty much every other vehicle on the planet. Today, Tesla shared its 48V implementation documentation with other major automakers — including competitors like Ford.

Ford’s own CEO Jim Farley confirmed the news on X, formerly Twitter, last night.

Tesla CEO Elon Musk also chimed in.

The consequences of Tesla’s actions won’t be immediately obvious in any other carmaker’s products, as they will likely take a long time to manifest into any real changes for the industry — if they do at all. But let’s take a step back.

Why does 48V architecture matter?

48V architecture is a huge deal not because it enables any particular feature or capability for any one car, but because it will lead to a step change in how automakers wire, accessorize, and electrically engineer their vehicles.

The first mass-produced vehicles generally used 6V architecture to power things like headlamps, and the industry broadly began to adopt 12V electrics in the 1950s. By the late 1960s, almost every car on sale in the US used 12V electrics — power windows, interior lighting, cigarette lighters, brake lights, ignition spark, batteries, and more all unified around this common voltage standard. This change was a big deal, because it meant that the suppliers who built a lot of these electrically-driven components could easily adapt their products to work with any car. Parts became yet more standardized (plus, more affordable and reliable), and eventually 12V became the universal standard for vehicle electrics.

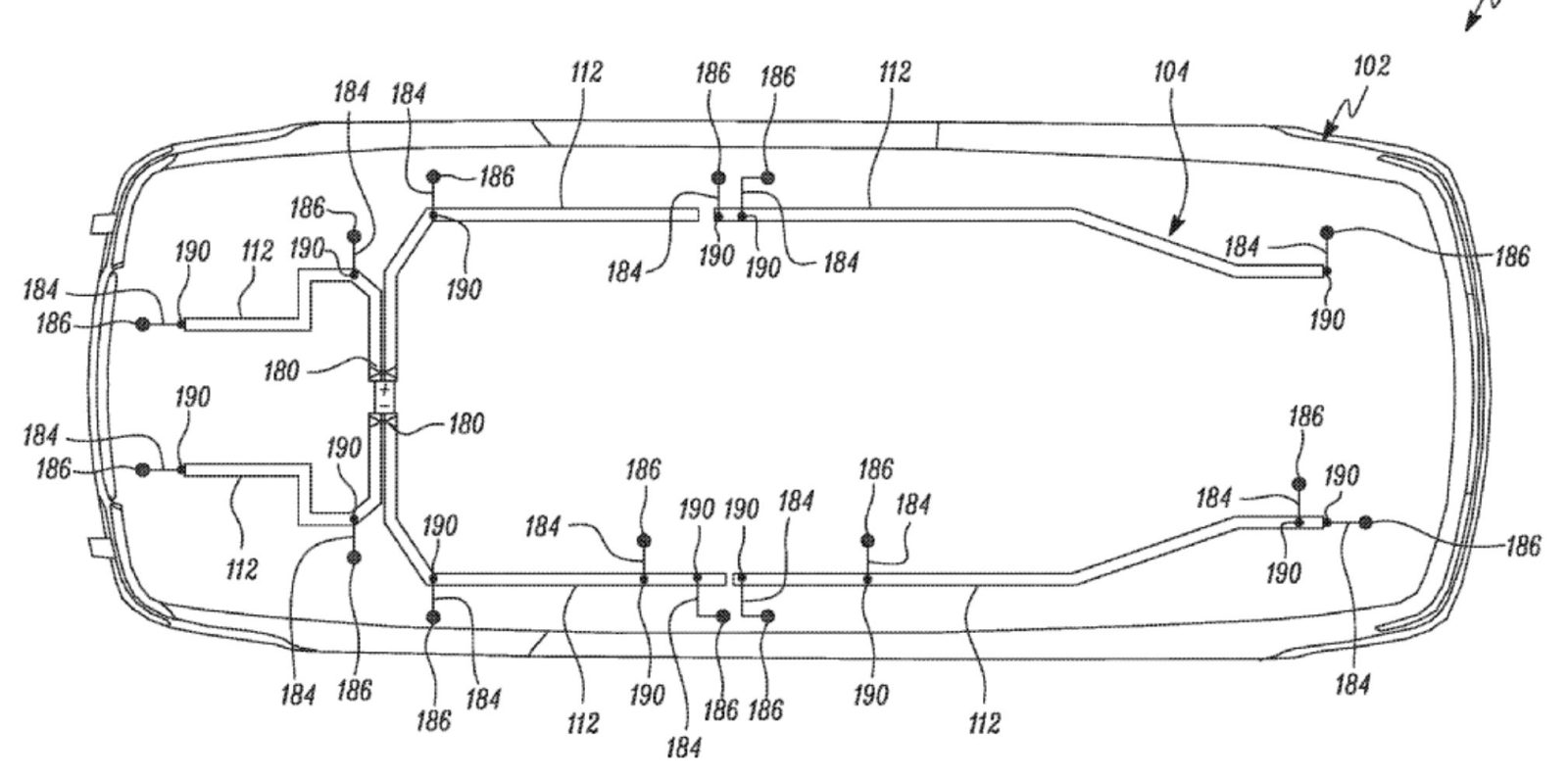

The problems with 12V architecture, though, have been looming (pun intended) for years. Because of the low voltage of this architecture, delivering sufficient power to all vehicle systems that need electricity became more and more complex. And as cars integrated more and more electrical components over the years, this led to ruinously complicated vehicle wiring layouts. (I want to be clear: I am vastly oversimplifying the nature of the challenges of 12V architecture, and it should be obvious by now I’m not an electrical engineer. I probably shouldn’t be allowed to be too close to a wall outlet, frankly.)

Switching to 48V architecture alleviates a huge number of challenges automakers are facing with 12V. The biggest one, though, is complexity: You need far less complex wiring harnesses to power all your vehicle systems, because each wire can supply far more power and voltage in a 48V system. 48V architecture also potentially improves overall electrical efficiency for reasons that I am not sufficiently qualified to explain beyond a kindergarten level, meaning your car’s accessory systems may require less power overall to operate (quite important for an EV).

12V roadblocks remain despite Tesla’s action

The challenge in adopting 48V architecture primarily lays in the vehicle supplier ecosystem, but that conclusion requires a bit of context setting.

If you cannot convert all of a vehicle’s systems to 48V architecture, the benefits of using such an architecture start to diminish pretty quickly in the form of introducing new complexities (i.e., a hybrid 48V / 12V vehicle architecture). As such, most automakers have clung to 12V because they know it and it works.

If an automaker decides to move to a 48V architecture, whatever car it builds must use 48V-ready accessories. But, suppliers aren’t incentivized to build such accessories without sufficient demand. While carmakers like Ford certainly have the power and scale to commission 48V parts independently, the per-unit cost of those components is likely to be substantially higher than their 12V equivalents — especially if they’re being produced in comparatively low volumes. And, many carmakers would be forced to make such a transition slowly over their entire vehicle lineup (it’s worth noting that ICE vehicles can use and would benefit greatly from 48V systems, too). And so, most carmakers stick with 12V. It’s a chicken-and-egg kind of issue.

Why did Tesla share its 48V architecture?

To be frank, Tesla isn’t sharing its 48V architecture from the Cybertruck for purely altruistic reasons. Once you understand the conundrum around vehicle suppliers in the 12V world and making a transition to 48V, things start to come into greater focus. Tesla knows that transitioning to 48V is going to be incredibly difficult for legacy OEMs, and while there is potentially upside for Tesla in such a change (more on that in a moment), this is something of a PR move.

By publishing its 48V architecture, Tesla is saying “OK, we’ll show you how we did this thing — a thing you say is really complicated and difficult and would take years to replicate. You can just copy us.” But Tesla knows full well that even a powerful and well-resourced company like Ford can’t spin up a 48V accessory supply chain overnight, and that such a change would incur very substantial non-recurring engineering work (NRE, as it’s known in some industries).

For Tesla, though, there are theoretical benefits in the event the wider industry switches to 48V vehicle systems. The biggest one is the supply chain. The more components in the global vehicle supply chain that are designed for 48V vehicle systems, the lower the cost of those components will become over time — through volume, competitive engineering, and increased reliability. The second is a bit more nebulous, but arguably just as important: Engineers and other skilled workers in the industry will coalesce their work and knowledge around 48V systems, reducing the amount of redundant work happening and increasing the number of workers in the hiring pool who can understand and innovate on Tesla’s systems (and who can bring their knowledge to Tesla, barring any intellectual property infringement, of course).

Electrek’s Take

It’s hard to see a downside to this move for anyone — for Tesla, the industry, or for the engineers designing the vehicle systems themselves. And it’s plain that the supplier ecosystem needs a kick in the pants to accelerate the transition to 48V, and that the benefits of such a transition are very substantial.

But it’s much harder to say how much of an impact Tesla’s decision to share its 48V design will actually have. Clearly, automakers are already incentivized to move to 48V, but doing so is challenging for a reason — it’s not just laziness. There are legitimate (if frustratingly financial and logistical) reasons that the 48V transition is moving along slowly.

It’s very possible that providing publicity around this relatively esoteric technical issue will be the greatest factor in instigating more aggressive work to implement 48V vehicle systems, as opposed to any technical know-how gleaned from Tesla’s documentation.

It should also be noted that Tesla has two distinct advantages in transitioning to 48V that legacy automakers do not. The first is being unusually vertically integrated in its approach to building vehicles — Tesla designs almost all of its own vehicle systems, even if they may be procured from third parties who actually manufacture them. The second is that Tesla doesn’t have many legacy vehicle designs to support or consider in deciding to transition electrical architectures. Put another way, Tesla’s focus on independent engineering and low legacy debt are huge reasons it can introduce a 48V vehicle while other auto OEMs continue to stick to 12V and likely will for years from now, even in their EVs. And simply telling other carmakers how it built a 48V system won’t change those realities overnight.

FTC: We use income earning auto affiliate links. More.